ELECTROLESS NICKEL (MIL-C-26074; AMS 2404)

Electroless Nickel

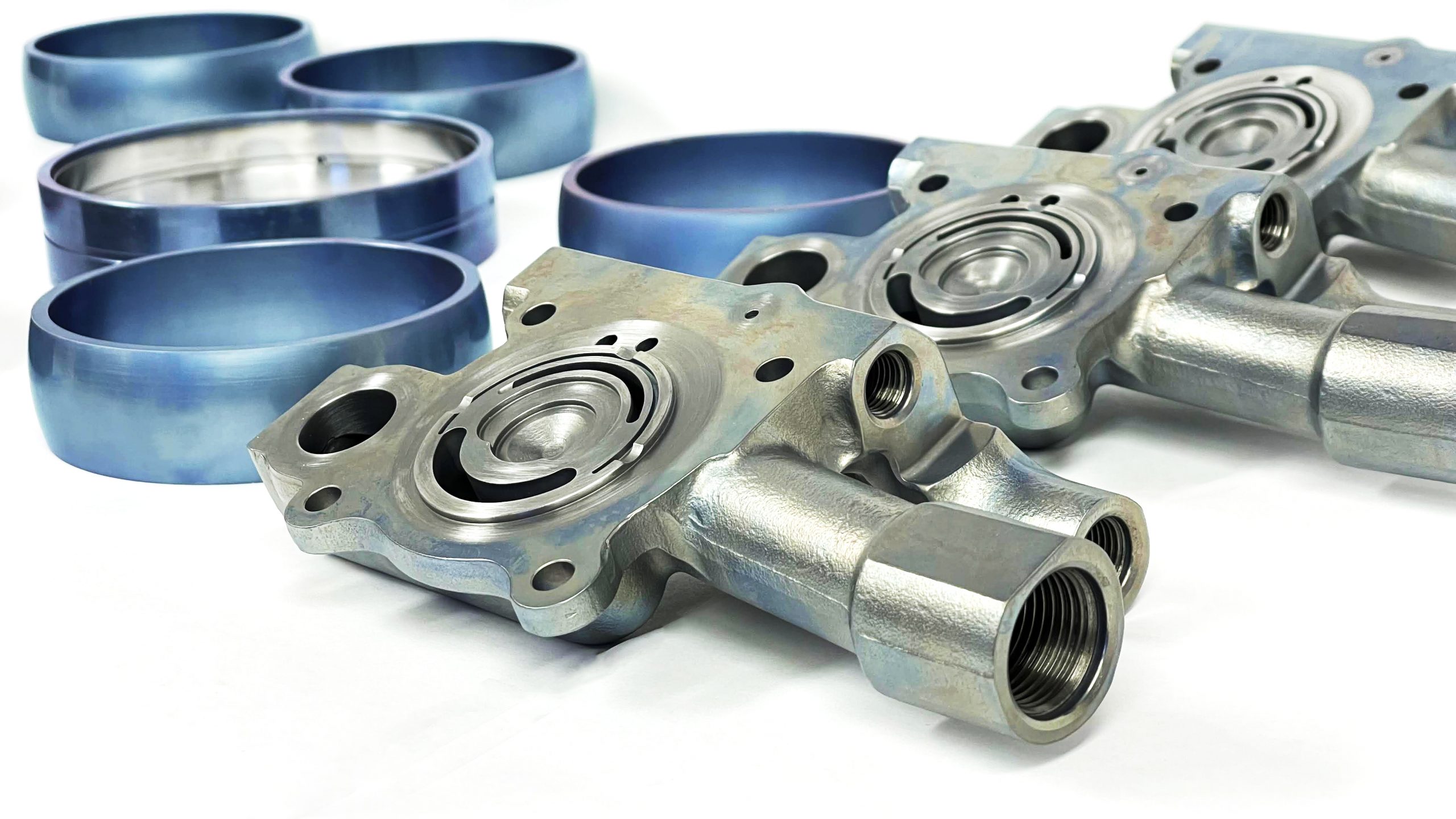

Electroless nickel is an engineering coating which has gained wide acceptance in the metal finishing industry due to its uniformity of deposits even in complex geometries, excellent corrosion properties and wear resistance. Because of these properties electroless nickel have found application in many industries

including the following petroleum, chemicals, plastics, optics, printing, aerospace, nuclear, automotive, electronics, computers, textiles, paper and food industries.

West Valley Plating offers a full array of electroless nickel processes: High Phosphorous, Medium Phosphorous, Low Phosphorous, Nickel Boron, Nano-Composites and Black Electroless Nickel. We offer both ROHS and Non-ROHS processes.

Black Electroless Nickel

Black Electroless Nickel Coatings are finding application in black decorative coatings, photo-thermal materials, absorbing materials, and within the aerospace and defense industries.

Low Phosphorous Electroless Nickel are deposits with a phosphorous content of 3 – 5%. These coatings have excellent properties such as wear resistance. They show very good corrosion resistance in alkaline environments.

Medium Phosphorous Electroless Nickel are deposits with phosphorous content of 6 – 9%. These deposits offer good corrosion protection and abrasion resistance.

High Phosphorous Electroless Nickel with a phosphorous content of 10 – 14%. These deposits are soft as plated but very hard after annealing. The deposits from high phosphorous electroless nickel are non-magnetic and can polish to a mirror fish. These properties are due to the amorphous structure of the deposit. They provide superior corrosion resistance in a variety of environments. They are widely used in acidic environments in the petroleum and chemical industry.

- Copper and Steel Mid Phos

- Electroless Nickel (Aluminum) Mid –Phos

- Electroless Nickel Teflon

- Electroless Nickel Teflon on Titanium

- Low Phos & High Phos Electroless Nickel

- Electroless Nickel on Beryllium – Upon Request

- Electroless Nickel on Magnesium – Upon Request

- Electroless Nickel Silicon Carbide – Upon Request

- Electroless Nickel Boron AMS 2433

SPECIAL ELECTROLESS NICKEL PROCESSES

Nano- composite Electroless Nickel

The mechanical and tribological properties of electroless nickel coating can be improved by the co-deposition of fine colloidal particles (particles size is the nanometer and micrometer range). The co-deposition of these fine hard colloidal particles with electroless nickel has generated a new family of coatings known as micro and nanocomposites. West Valley Plating offers the following composite electroless nickel processes: Electroless Nickel-Teflon, Electroless Nickel-Silicon Carbide, Electroless Nickel-Nanodiamonds.

Zinc Nickel (AMC 2417)

- Type I

- Type II – Grade A & B

Nickel Plating

Nickel Plating is widely used as an engineering coating due to its good corrosion properties, hardness, and wear resistance. These processes are used extensively for decorative, engineering, and electroforming purposes.

West Valley Plating offers the following types of nickel plating.

Bright Nickel – This type of nickel used as a final finish for decorative and engineering applications. These coating are fully bright. They are used as a barrier layer to reduce porosity and to improve corrosion resistance.

Sulfamate Nickel – These are soft coatings used for engineering applications. Often used for electroforming due to its ductility and are easy to machine. Deposits from this type of bath are produced with low stress.

Hard Nickel – This deposit is widely used in engineering applications due to its excellent hardness, wear resistance, improved abrasion resistance, greater tensile strength, and good ductility.

Black Nickel – Black Nickel Coatings are used in the industry in optical instruments, in absorption materials, in decorative coatings and in the aerospace and defense industries. These deposits have little wear or corrosion resistance and are usually deposited over a layer of bright nickel or electroless nickel.

Cadmium Plating

- AMS QQ-P-416 / ASTM 2400

- Type I Clear

- Type II (Chromate)

RARE AND EXOTIC METALS

- INCONEL

- TUNGSTEN

- KOVAR

- BERYLLIUM COPPER

- ALBEMET

- MONEL

- TELLURIUM COPPER

- INVAR

- WASPALOY

PLATING ON PLASTIC

- TEFLON

- ABS (ACRYLONITRILE)

- ABS (POLYCARBONATE)

- BUTADIENE STYRENE

- POLYCARBONATE PHENOLIC

*CALL IF PLASTIC TO BE PLATED IS NOT LISTED

NOTE: METALS THAT CAN BE PLATED ON PLASTIC

- GOLD

- NICKEL

- COPPER

PLATING ON CERAMICS

- ALUMINA

- STEATITE

- ZIRCONIA

- MULLITE

Our Plating Facility is dedicated mainly to serving Military, Satellite Aeronautical And Aerospace Applications, We currently have 70 Tanks that can handle most any Plating or Anodizing need. All Phases of our processes are rigorously controlled through completion.

Process Certifications are then issued and attached to shipping documents.

Rare and Exotic Metals are anodized or plated in a specialty rare and exotic metals processing in a separate and secure controlled room.

Other Electro Plating

- Tin Plate (Mil-T-10727)

- Bright Nickel (QQ-N-290)

- Copper Plating (Mil-C-14450)

- Silver Plating

- Gold Plating

- Sulfamate Nickel

Special Process

MAGNESIUM PROCESSES

- Dow # 1 Upon Request

- Dow # 7 Upon Request

- Dow # 10 Upon Request